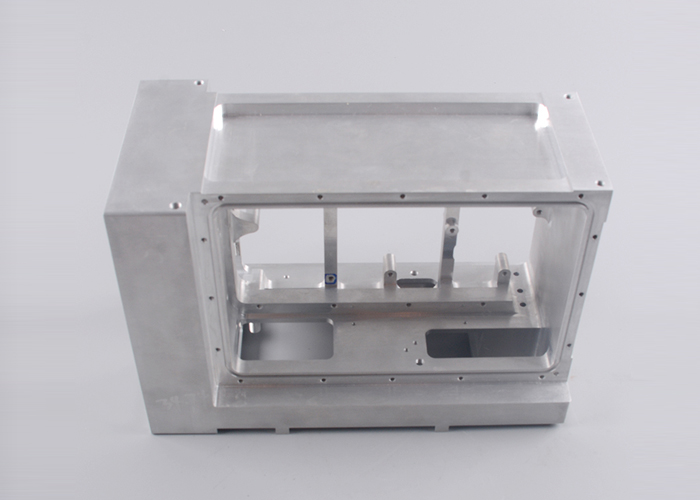

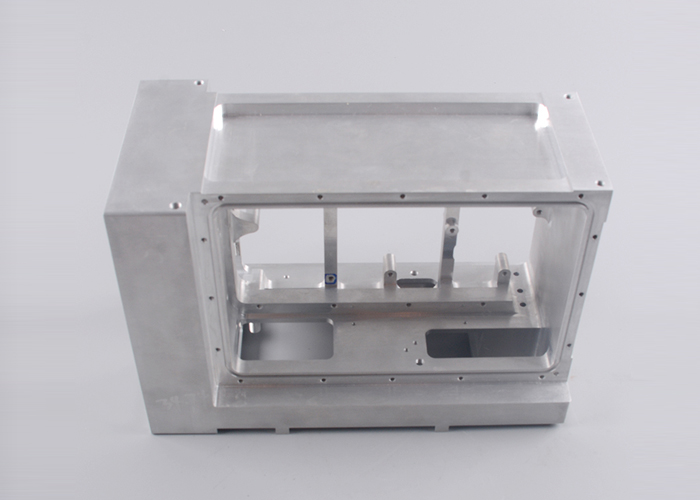

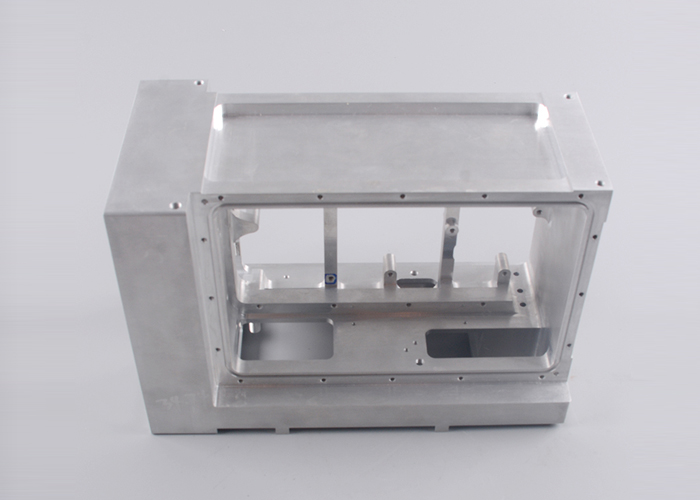

3D printing and CNC machining in some cases often work in concert to produce end - use parts.the metal parts passes through the 3D printing,CNC machiningMay be used for precision milling characteristics and improvement in quality, with the aid of the CNC machining in a secondary operation is critical, and may require a higher level of finishing of the part on the characteristics of the hole and can be finely adjusted.3D printingContinuing along the path of robust growth. With the functions of the development in the past few years, as can be seen the 3D printing of breathtaking technical progress and development.Comparatively, the machining is still here and continue with the development of 3D printing technology together.Thirty years ago, CNC machining compared to faster, more accurate, cheaper and in support of their tools and software also and made remarkable progress, the programming system is more advanced, easier to control the machine operation,Cutting tool machining equipment than its predecessors and more rapid removal of the metal.

Design for the purchase of spare parts and those who want them to have a precise, accurate and accurate material quantity, soon they will want them.Their customers.Product development cycles and more compact.Mass Customization and the trend is accelerating the listing of the company on a day - to - day legal challenge.To take advantage of those technologies, design and machining parts purchasing person must grow in a different way of thinking, must accept the traditional process of digitization,As processing 3D CAD models drawings must become the product lifecycle aspects of the reference document, must be communicated to the manufacturer the requirements of the standard.These digital transactions has long been a standard for 3D printing, but also are quickly becoming the standard CNC machining, at least now can achieve previously out of reach to low - volume custom, this is our These digital revolution in fabrication of the key?We must continue to adopt new technology, and to embrace the ever - changing digital environment.We can do this.