CNC MACHINING

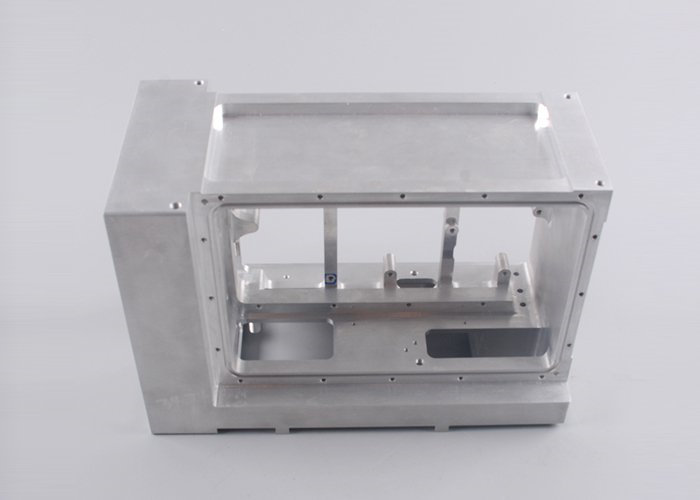

Our center features vertical and horizontal machining centers to deliver an extra level of precision and productivity. We also offer CNC milling,lathing , turning and drilling to accommodate the variety of product sizes and cuts in circulation today. Our team works with several different materials as well, from copper and aluminum to steel and other metals,as well as all kinds of plastic.