-

Hand proofing, what does that mean?Hand proofing what needs attention?

Plank of proofing means according to the guest, as such or in the artwork, by machining the sample, which is designed according to the designer of the 3d drawing to make a sample of the product, is used to detect the products of the structure.Can mean sampling purposes, for reference, that is, the hand model, it is possible to make sure the bulk of the sample quality, style and color, is entered into a contract, and provide a basis for proofs of the finger is flexible and can be adapted in many ways.Proofing plank then what needs attention? hand proofing Good design requires a corresponding 3d of the drawings, because the 3d - made sample is made to the drawings, and if you're drawing too much from the size of the product for it even at the board, and the manufacturer later processing, the detection accuracy of the time are still going to be very different.In the finger plates and proofing, confidentiality is also very important, plank of proofing is when one is able to independently complete plank - making factories, eliminating the need for outsourcing, 3d of the drawings is also not to be more and more people know,So as to protect your intellectual property.You need to get a good board, and the manufacturers of proofing, if you find the manufacturer of the boards had no power, not only in the delivery can give rise to problems, even in terms of quality, it is difficult to guarantee.Feng Rui model can independently complete models with all of the proofing process, and is high in accuracy, speed, and a variety of mechanisms for the protection of confidentiality, is a board of powerful companies and industries.

-

Modeling proofing processing price is how calculative?

Most people came along and asked how much boards needed to do this, we must be clear, hand model is a custom class OEM products, there is a need to provide the corresponding design drawing, it is necessary to know the customer's board, and the specific dimensions, it knows that the figures and also made a reference to other factors of the compute to its board prices,quotes relating to the coordination of the entire demand for oil products, the same similar - looking products, multi - step prices is very different, models with quotation according to FIG. 3D is an analysis of the product size,And there is a need for a process and a machining time of the offer.Of course a different board, and the processing technology of the reference prices for the different factors.

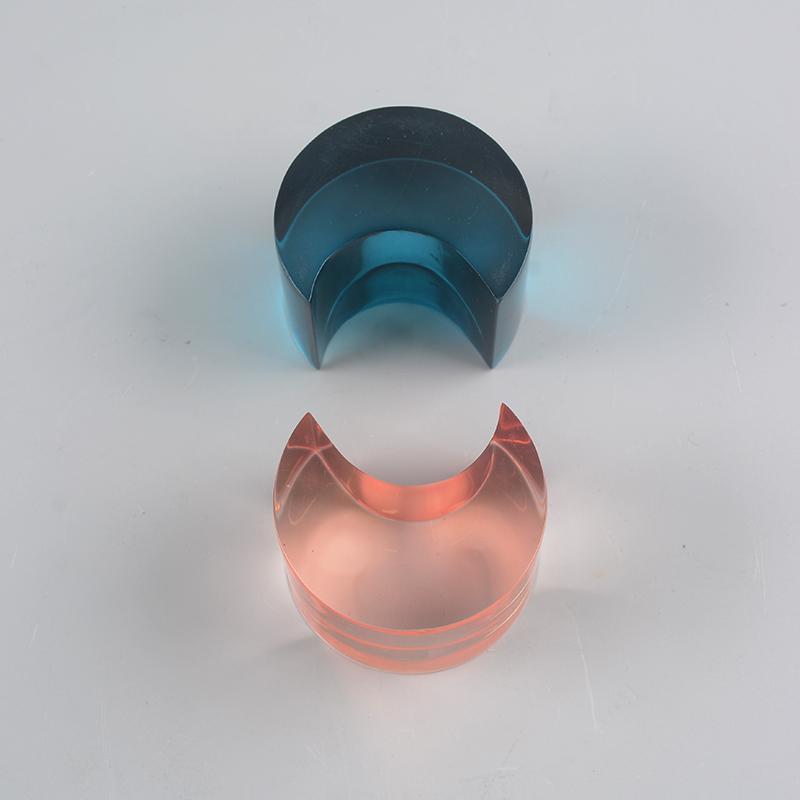

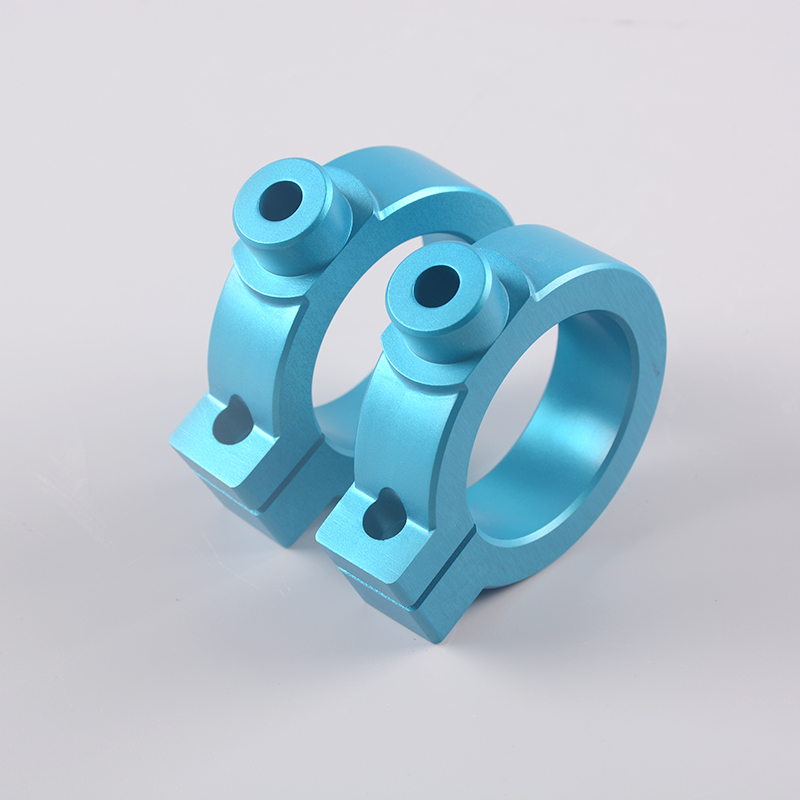

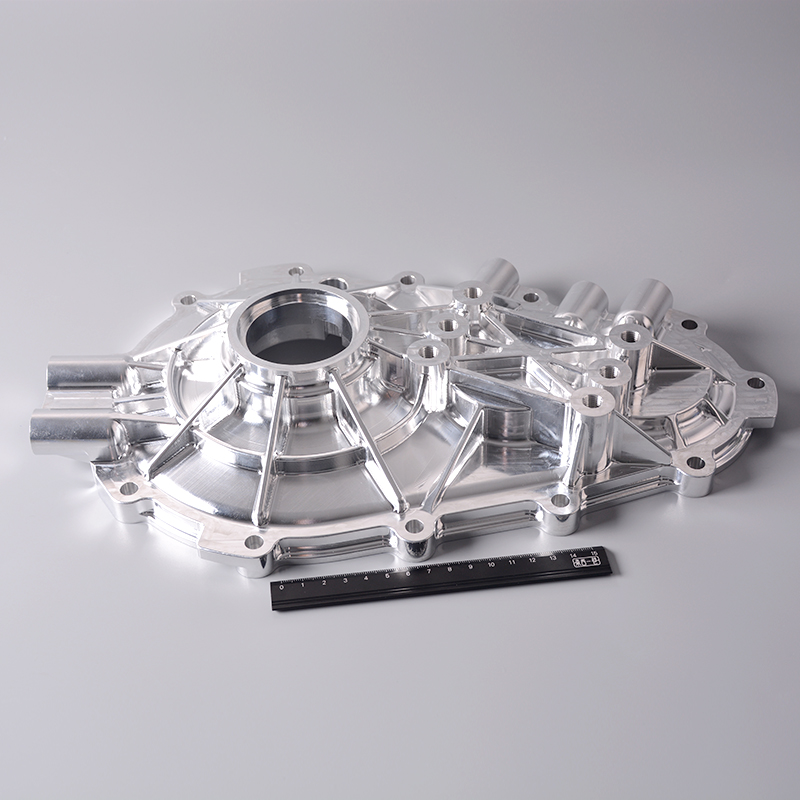

3D printing according to the material and the price is calculated as the weight of the other surface of the treatment cost, if you're gonna do the plank suitable 3d printing,We will use your drawings of 3d calculate your finger on raw materials (by weight of the portafilter are typically in units of g), and then multiplying by one gram of the raw - material prices, the prices of raw materials is also low among materials also are hierarchical,Is to see a 3D printer and applicable customer requirements, the material of the good points of the price is expensive. If you're doing cnc plank, consider that you needed a hand plate of the surface treatment needs are used to process the more, the higher the price is natural also, secondly, to look at the board, and the size and complexity,These two factors are directly proportional to the plank, the larger the size, and material is also more complex and more difficult, more time consuming, price nature is also high;Finally is the accuracy requirement, if the high precision demand (such as 0. 01mm) and high machining precision of equipment and technology as well as artificial demand also increased, production cost, so the prices are also subject to change. If the finger is doing the bulk of the required vacuum casting job doing this process, the board, and the price it needs from the model of the price, the price of each complex die board, and the price of these three price added to arrive at the exact price.This is because due to the recovery mode vacuum beforehand using a CNC or 3D - printed and made out a hand model, and then based on the Modeling of a silica gel mold, and then passed through a silica gel mold replication product.

-

Structural models with very different from what?

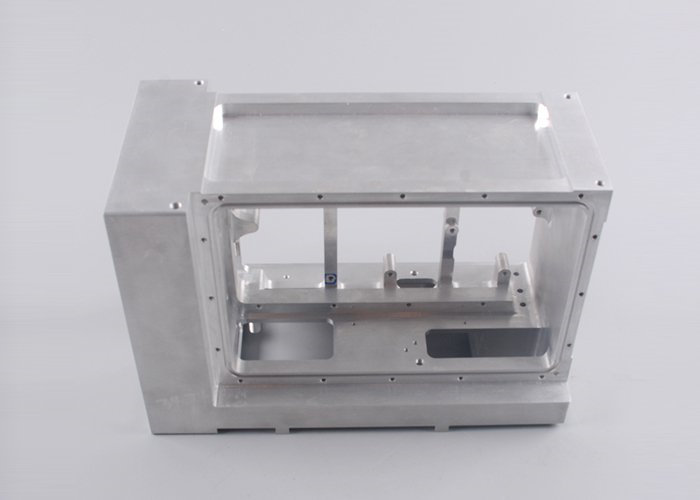

mould structure are used to validate the rationality of product structure, scaffold dimensions required for a more accurate, opponents plate appearance requirements are relatively low, foreign customer's requirements are particularly stringent, the scaffold structure can directly show the structure of region,Installation of the degree of difficulty, easy to find and solve problems.If the handle panel from a functionality point of view, it can be divided into the appearance of the plank and a plank structure.Non - plank structure is also called a plate appearance, only to see the appearance of, there is no need for the activities of the so - called black - and - white appearance of the finger plates is only required board, and the look - and - design products similar to or identical with respect to the products, not requiring it can,Thus the products are not for sale, mainly for the exhibition, in order to complete the earlier period propaganda work. While the structure is / are movable, it can be seen that the function of the plank, the plank structure is hollow inside, can be used to integrate electronic components, can also be used as a finished product, for example, and the structure of boards that are to have a body, wheels, doors, etc.As long as the general appearance, there is a kind of want to have, but are scattered around the assembled workpiece, so that the structure of hand - board model manufacture is relatively complicated, each location being sized to achieve a very precise, otherwise the installation will be a problem.

-

Hand proofing what needs attention?

Now a lot of people don't know hand proofing Actually, boards, also called a sample, or rapid prototyping, also known as a first plate,it is simply the new products at the stage of research and development, in order to physically verified in the future to the production process and function of the first template, are not listed in the product before the appearance of an assembly or of the sample, is to see the decorative effect of a product,Or assembling structure of the earlier products, if the appearance of the problem, the structure can be subjected to the next working station, and, in the design's better you make sample check assembly issues, etc.Feng Rui model today to tell you about finger proof ought to be paying attention. First, the board needs to design good proofing product 3d of the drawings, the finger plates is in accordance with the 3D drawings, 3D drawings. If you don't tell you the size of the demand, then the manufacturer of your perfect scaffold according to design drawings to processing,Man cannot be always your design needs, the design drawing is very important, Second, find a good board, and the manufacturer of the textile sample is also very important, good producers of the palm, represents the power efficiency, strength, quality and service, if the board manufacturers had no power, there may occur problems, such as delivery problems, quality issues,Service issues, etc., can lead to a prolonged period of product development, cost is increased.- there are many boards that manufacturers are 2 - 3 machine 2 - 3 Small, personal, hand - board model manufacture technical process, this small workshop easily appearing problems, Finally, the hand plate to proofing, confidentiality is also very important, this is a creative designer of the design of intellectual property rights, such as the patent disclosure,So the hand plate making process to find a time to complete an independent hand - board model manufacture does not need to set out the manufacturers, and manufacturers also have associated security mechanism, the products of 3d of the drawings is also not to be more and more people know,So that the effective protection of your intellectual property.Feng Rui model not only can independently complete board production process, also has a tripartite security mechanism to protect your design drawing is not compromised, with their years of hand - board model manufacture experience, advanced equipment, professional hand proofing Shifu, services and technology to improve the team,- this is the finger.

-

General processing Shouban have common?

Production of CNC Sample for verification of product design whether reasonable, whether the product complies with the requirements of use, it is possible to detect the products of the structure, appearance, function;In doing planks are required before a ready 3D models with design drawings, 3D drawings generally is the IGS, STP, PRT, XTL file, on the basis of the drawings is designed to be machined by means of a board,According to do boards have several common processing methods: 3D printingLaser rapid prototyping is: SLA / SLS, may not be restricted by the shape, it is possible to print any complicated shape of the finger, the more complicated, which may embody the advantages of the technology of 3D printing, no matter how complex, can be printed out,It has the advantage of reducing the production cost and time cost.The manner is charged by weight, if a large volume of scaffold with 3D printing in such a way to do it. cnc machining : the process is very extensive, in addition to the soft type, other plastic and metal materials may be processed, and out of the machining precision can reach 0. 02 - 0. 10 mm;He is distinguished by a high speed, high strength, large - size machining, CNC machining of the shape may be limited, if it is too complicated, then the member needs to be removed. " vacuum casting job: for small batch production, need to do first, before you go on to a silica gel mold, the silicone mold production cycle is short, cheap, easy to dominate the field, suitable for use in small hand - board model manufactureA silica gel mold can be made 10 - 15 by the right and left;re - use is likely to occur, deformation, shrinkage, etc., under vacuum conditions, the castable for defoaming, stirring, preheating, casting, and subjected to secondary curing in an oven,Silica gel mold of hand model can reach up to ABS functions.During the strength of the material quality and hardness.