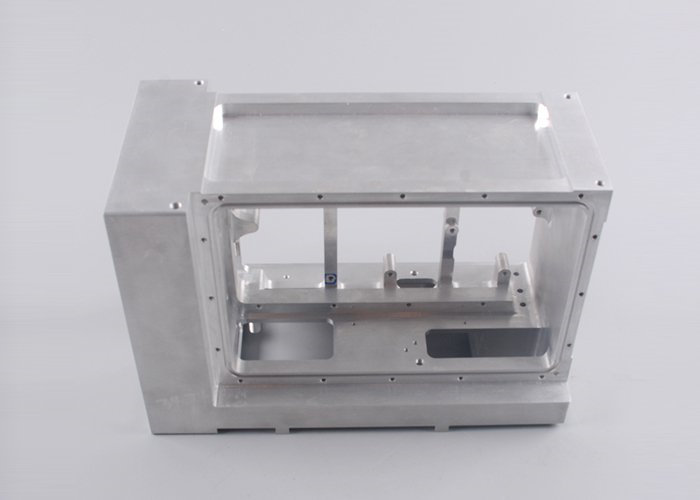

SHEET METAL

Sheet metal processing is a broad concept that covers a large number of machining operations applied to metal sheets.

Assembling/Autogenous cutting (fire cutting)/Boring/Coating/Cutting/Deburring/Drilling/Edge rounding/deburring/silking/Edging/bending/Galvanizing/Laser Cutting/Milling/Plasma cutting/Punching/Sawing/(Smooth) rolling mills/Tapping/Welding/Water Cutting......