Material Capacity

Choose from hundreds of commercial-grade plastic, metal materials suitable for both prototyping and production.

| Name | Type | Description | Processing |

| nylon | PA12 | may be dependent on the petrochemical industry.Semicrystalline - crystalline thermoplastic material.Its characteristics and PA11 is similar, but different crystal structure.PA12 is a good electrical insulator and the like and other polyamide due to humidity or not so as to ensure the insulation. | |

| nylon | PA66 | Nylon 6, and thus its mechanical strength, rigidity, heat resistance and wear resistance, creep resistance and better, but the impact strength and mechanical shock - absorbing performance is lowered, and is well - suited to the automatic lathe machining.PA66 is more widely applied in automobile industry, instrument housing and other needs have impact resistance and high strength requirements of the product. | |

| nylon | PA6 | The material having the most superior combination of properties, including mechanical strength, stiffness, toughness, wear resistance and mechanical shock absorption.These characteristics, combined with good chemical resistance and electrical insulating ability, so that the nylon 6 to become a "generic" material, for mechanical structure parts and maintainable parts. | |

| PEEK | PEEK | Polyetheretherketone (PEEK) resin is a kind of high performance plastics, and other specialty advantages compared with much more significant, positive resistance - temperature 260 degree, excellent mechanical properties, self - lubricating, anti - chemical corrosion, flame retardant,Exfoliation resistance, wear resistance, are not resistant to strong nitric acid, sulfuric acid, radiation resistance, outstanding mechanical property can be used in high end of the mechanical, aeronautical and nuclear engineering and technology. | |

| PET | PET | Polyethylene terephthalate is a thermoplastic polyester in which most of the major varieties, commonly known as the polyester resin.It is made up of dimethyl terephthalate with ethylene glycol or transesterification of terephthalic acid with ethylene glycol in the esterification of the syntheses of bis (2 - hydroxyethyl) terephthalate, and then subjected to polycondensation.With PBT together as a thermoplastic polyester, or a saturated polyester.in a broad temperature range and has excellent physical and mechanical properties, the temperature can reach 120 degree over along period of use, an excellent electrical insulation even at high temperature under high frequency, its properties become good, but the corona resistance, creep resistance, fatigue resistance,Rub resistance, dimensional stability is excellent. | |

| PBT | PBT | polybutylene terephthalate, polybutylene terephthalate (PBT), polyester series,is 1.4 - butanediol pbt (1. 4 - glycol and terephthalic acid (PTA) or terephthalate (DMT) poly - condensation,And via a mixing procedure that is made of a milky white translucent to opaque, crystalline thermoplastic polyester resin.PET together as a thermoplastic polyester, or a saturated polyester.household utensils (food processing blades, vacuum cleaners, electric fans, hair dryers, coffee, etc.), electrical (switch, the motor housing, a fuse box, a computer keyboard key, etc.), industrial (automobile radiator grill,Vehicle body panels, wheel covers, doors, etc.). | |

| PC | PC | polycarbonate (PC) is a molecular chain of carbonic acid in the ester group of the polymer, according to the ester group of the structure can be divided into aliphatic, aromatic, aliphatic - aromatic, and so on.Wherein the aliphatic and aliphatic - aromatic polycarbonate of the mechanically relatively low, thereby limiting its use in engineering plastics applications.PC engineering plastics for three major field of application is the glazing industry, automobile parts, electric, electrical appliance industry, followed by industrial machine parts, optical discs, packaging, computer and other office equipment, medical and health care, films, leisure and protective equipment etc. | |

| polyurethane (PU) | PU | Polyurethane is a class of polymers with NHCOO-repetitive structural units in the main chain. The acronym PU includes rigid polyurethane plastics, soft polyurethane plastics, polyurethane elastomers and other forms. It can be divided into two categories: thermoplasticity and thermosetting. Its raw materials are usually in resin state. | |

| PVC | PVC | Initiators such as peroxides and azo compounds, or polymers formed by free radical polymerization under the action of light and heat. The homopolymer of vinyl chloride and the copolymer of vinyl chloride are collectively called vinyl chloride resin. PVC was once the world's largest production of general plastics, widely used. It is widely used in building materials, industrial products, daily necessities, floor leather, floor tiles, artificial leather, pipes, wires and cables, packaging film, bottles, foaming materials, sealing materials, fibers and so on. | |

| PP | PP | Polypropylene is a thermoplastic resin prepared by polymerization of propylene. The relative density is only 0.89-0.91, which is one of the lightest varieties in plastics. Because of its high crystallinity, the surface stiffness and scratch resistance of this material are very good. There is no environmental stress cracking in PP. | |

| PPS | PPS | PPS plastics (polyphenylene sulfide) is a special thermoplastic engineering plastics with excellent comprehensive properties. Its outstanding characteristics are high temperature resistance, corrosion resistance and excellent mechanical properties. Electrical insulation (especially high frequency insulation) is excellent, white hard and brittle, falling on the ground metal noise, light transmittance is second only to plexiglass, colouring resistance, water resistance, chemical stability is good. It has excellent flame retardancy and is non-flammable plastic. General strength, good rigidity, but brittle, prone to stress brittle cracking; not resistant to benzene, gasoline and other organic solvents; long-term use temperature can reach 260 degrees, in 400 degrees of air or nitrogen to maintain stability. By adding glass fiber or other reinforcing materials, the impact strength can be greatly improved, heat resistance and other mechanical properties can also be improved, the density increased to 1.6-1.9, the forming shrinkage rate is less than 0.15-0.25%, suitable for making heat-resistant parts, insulating parts, chemical instruments, optical instruments and other parts. |

Hand making

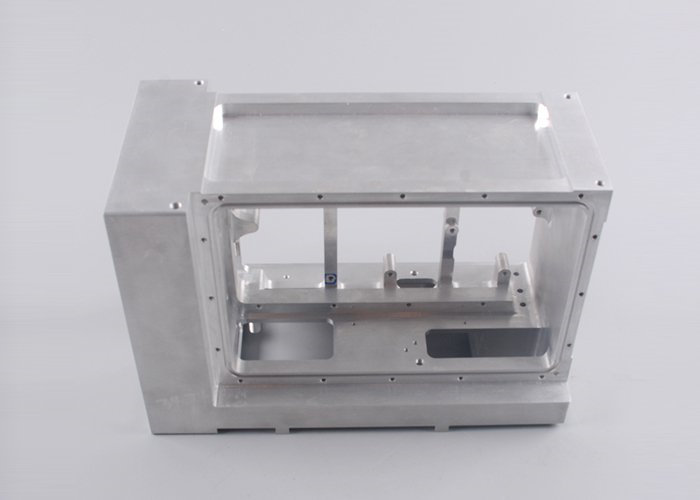

CNC processing

3D printing

Small batch film coating

surface treatment

|

| Acrylic | PMMA | chemical stability, mechanical properties and weatherability, easy to dye, easy processing, beautiful appearance.Gelatin is also known as plexiglass, glass, acryl and the like.The material which is widely used for advertising lightbox, nameplate, etc. | |

| POM contest steel | POM contest steel | POM is a tough and elastic material, even at low temperatures still have good creep resistance properties, geometric stability and impact resistance characteristics.Existing material POM homopolymer but also copolymer material.Homopolymer material has good tensile strength, fatigue resistance, but is not easily processed.Copolymer material with good thermal stability, chemical stability and ease of processing. | |

| ABS plastic | ABS plastic | textile and construction industries, is an extremely useful thermoplastic engineering plastics.ABS is generally pale yellow or milky white noncrystalline resin pellets.ABS is one of the most widely used engineering plastics. | |

| PTFE Teflon | PTFE | The invention relates to a fluorine - substituted polyethylene in which all of the studies of synthetic polymer material.Such a material having the alkali - resistant, acid - resistant, resistant to various organic solvents, are practically insoluble in all solvents.At the same time, the polytetrafluoroethylene having a characteristic which is resistant to high temperatures, its low coefficient of friction, it may be a lubricating effect, also became a nonstick pan and a water pipe inner layer of material. |